|

|

|||

|

|||

|

|

|||

|

|||

|

|

|||

|

|

|||

ABOUT US

|

·

Dettinger

Project Management established in 1994. We provided services to the

wood products industry for over 20 years, specializing in energy production

and drying technology. ·

We provide engineering services

and products for clients in USA, Canada, New Zealand, Europe, South America

and Indonesia. ·

Heinz

Dettinger, the proprietor of Dettinger Project Management,

takes pride in the engineering work and treats each project with exceptional

care. ·

Our

goal is to provide our customers with excellent service, cost effective

solutions and outstanding results. ·

Our

mission is to find opportunities, develop new ways to make better products

and improve on existing technologies. ·

We

strive to exceed our client's expectations by providing exceptional value. |

ENGINEERING

|

Conceptual

engineering is the road map for a successful

project. It is the first step to start a project, establish parameters and

define how we achieve the goal. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Our Answer Ø We confirm your goal and develop a

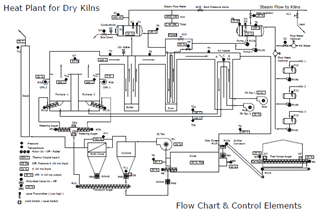

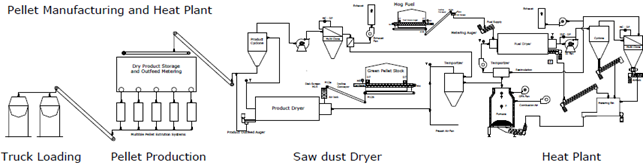

plan. Ø We prepare a process flow chart. Ø We develop a time table. (Gantt

Chart) Ø We make a list of equipment for the

project. Ø We evaluate the environmental impact

and propose solutions. Ø We estimate the energy requirement

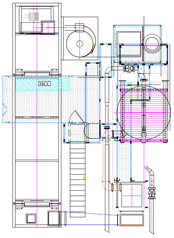

and other resources. Ø We develop a facility layout based

on available space. Ø We prepare a budget for the project.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||